The unique anatomy of tissue interfaces

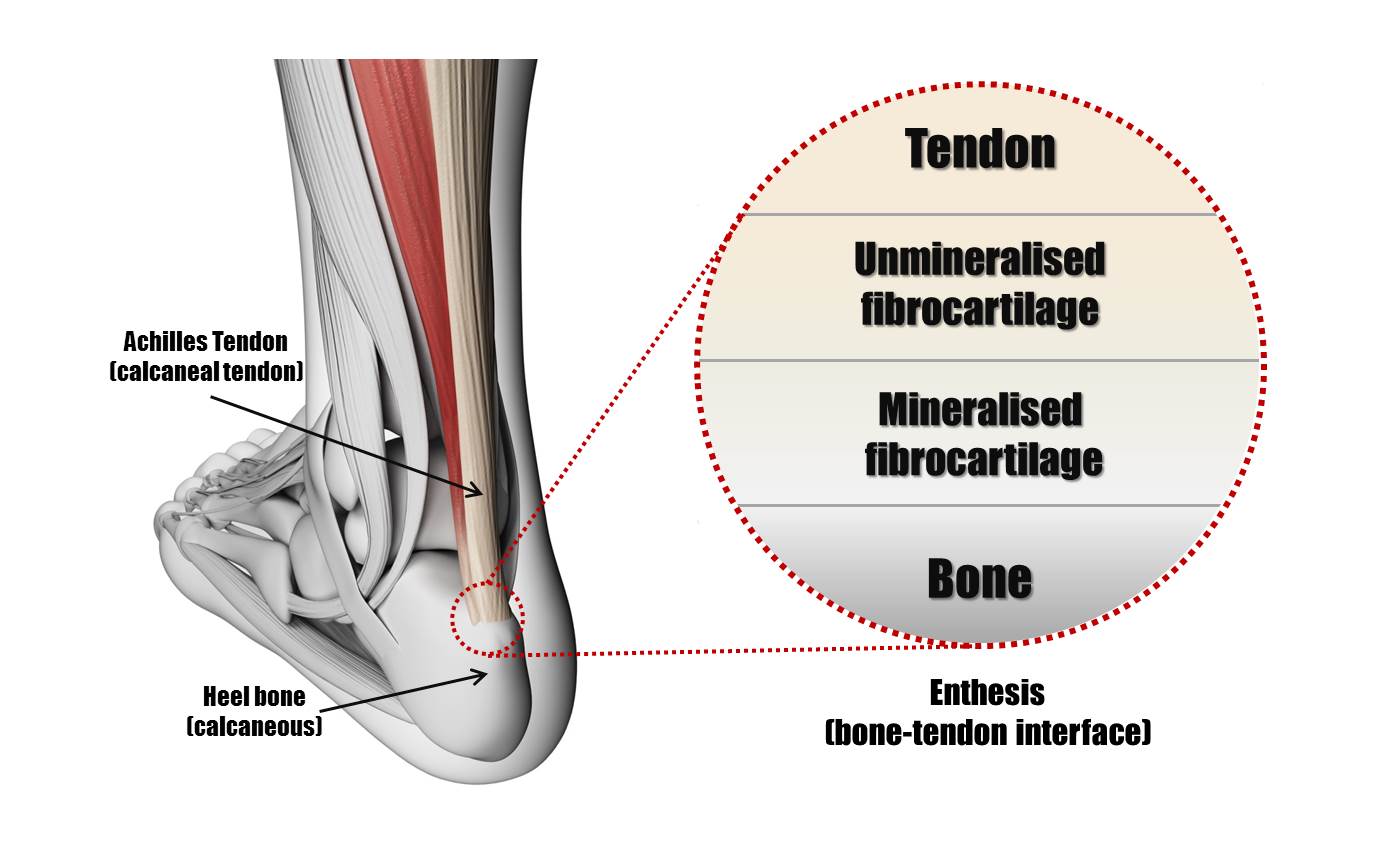

The anatomical structures of tissue transitions are fundamental to their function. These transitions are biochemically and biomechanically adapted to allow smooth transfer of force between tissues with varying mechanical properties. For example, the force generated by muscle contraction must travel from a compliant tendon to a stiff bone to facilitate movement. The bone-tendon junction is therefore adapted to achieve this, with a gradual increase in mineralisation from tendon to bone, the presence of fibrocartilage at the interface and changes in the alignment of collagen fibres (Figure 1). Similar adaptations are seen throughout the body at tissue junctions and so it is important to establish adequate transition points if engineered tissues are to become a realistic possibility for implantation.

Figure 1. The anatomy of the bone-tendon interface (enthesis). The transition between tendon and bone contains several regions. The gradual change in mechanical properties helps to transfer stress smoothly.

Interfacial Tissue Engineering

Tissue engineering seeks to

manufacture replacement tissues in the laboratory using a combination of

biological and engineering principles. While many groups concentrate on the

engineering of particular tissues in isolation, a subset of tissue engineering

research has emerged recently, called interfacial tissue engineering, which

attempts to re-establish the complex interfaces found at the junctions between

tissues as described above.

The Paxton Lab focusses on interfacial

tissue engineering of the musculoskeletal system and our research can be split

into three related and complementary topics;

1)

Understanding

the mechanisms of musculoskeletal tissue interface formation in vitro

Using

2D and 3D culture systems, we are investigating cellular co-cultures to examine

their behaviour, organisation and interaction.

2) The manufacture of complete multiphasic tissue

structures for implantation

Using a combination of

scaffolds and cell populations, we are investigating the manufacture of

complete bone-to-bone ligaments, osteochondral plugs and bone-tendon

replacements for implantation following injury.

3)

Developing 3-dimentional in vitro models for

understanding musculoskeletal disease and repair.

Our 3D culture systems can be a useful model for the

study of musculoskeletal disease or for the investigation into repair options

following injury.

For anymore information about our research, or if you are interested in collaborating then please contact us using the details provided.